Gobar Biogas Plant Biogas Tank Cost Biogas Plant Project Price

Biogas Plant Introduction:

High levels of methane are produced when manure is stored under

anaerobic conditions. During storage and when manure has been

applied to the land, nitrous oxide is also produced as a byproduct

of the denitrification process. Nitrous oxide (N2O) is 320 times

more aggressive as a greenhouse gas than carbon dioxide[23] and

methane 25 times more than carbon dioxide by converting cow manure

into methane biogas via anaerobic digestion, the millions of cattle

in the United States would be able to produce 100 billion kilowatt

hours of electricity, enough to power millions of homes across the

United States. In fact, one cow can produce enough manure in one

day to generate 3 kilowatt hours of electricity; only 2.4 kilowatt

hours of electricity are needed to power a single 100-watt light

bulb for one day. Furthermore, by converting cattle manure into

methane biogas instead of letting it decompose, global warming

gases could be reduced by 99 million metric tons or 4%.

Biogas Plant Specification:

| Biogas Plant Components | Pretreatment equipment, anaerobic reactor, biogas purification

equipment, biogas utilization equipment, other related equipment |

| Device Name | Anaerobic Reactor |

| Process type | Internal Circulation Anaerobic Reactor—IC/UASB/ EGSB |

| Specifications | According to customers |

| Manner of preservation | Epoxy Coal Asphalt Paint or Electrophoresis |

| Installation Method and Construction Cycle | Inverted Installation Process—50d(Anchor Splicing)/100d(Welding) |

| Material | Q235B |

| Stir Method | Internal Circulation Stir |

| Advantage | Processing High, Medium and Low Organic Waste Water |

| Field of application | Organic Waste manure or waste water |

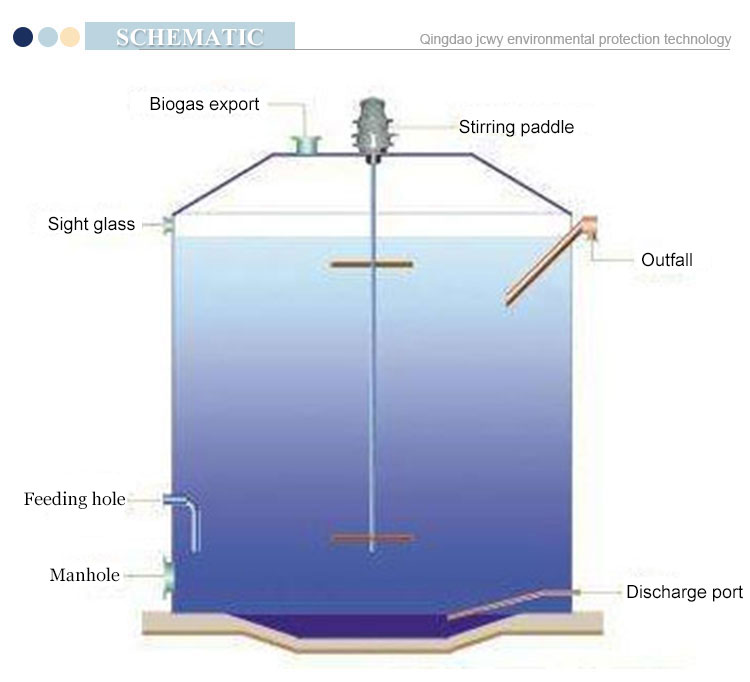

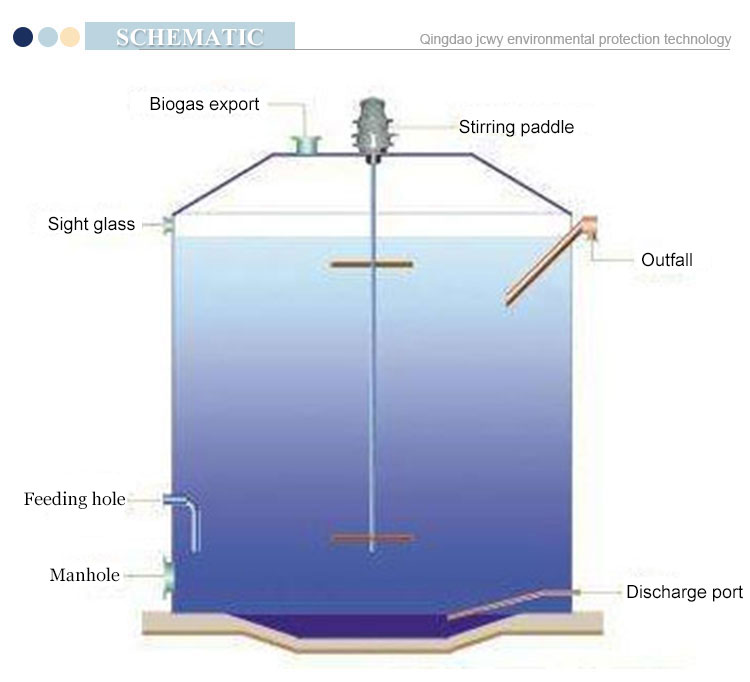

Biogas Plant Core Equipment Schematic:

Biogas Plant Core Unit Advantages:

1. The reactor is capable of processing raw materials having a high

suspended matter content;

2. The temperature inside of the fermenter is evenly distributed;

3. The material in the anaerobic fermentation tank is evenly

distributed;

4. The anaerobic fermenter has high impact load resistance;

5. Anaerobic fermenters avoid scum, crusts, blockages, poor gas

escape and short-flow phenomena;

6. Combined with flexible airbags, it is an integrated device,

saving investment and land occupation. It is one of the most

advanced anaerobic reactors in the world.

Biogas Plant equipments:

Biogas Plant Package:

Our Company Introduction: