Qingdao Jingcheng Weiye Environmental Protection Technology Co., Ltd

Qingdao JCWY Environmental Protection Technology Co., LTD., is a

scientific and technological enterprise mainly engaged in the

development of new energy industry, environmental protection

sewage, air pollution control, large-scale biogas project design,

construction general contracting and integrated equipment R&D,

production, sales and service.

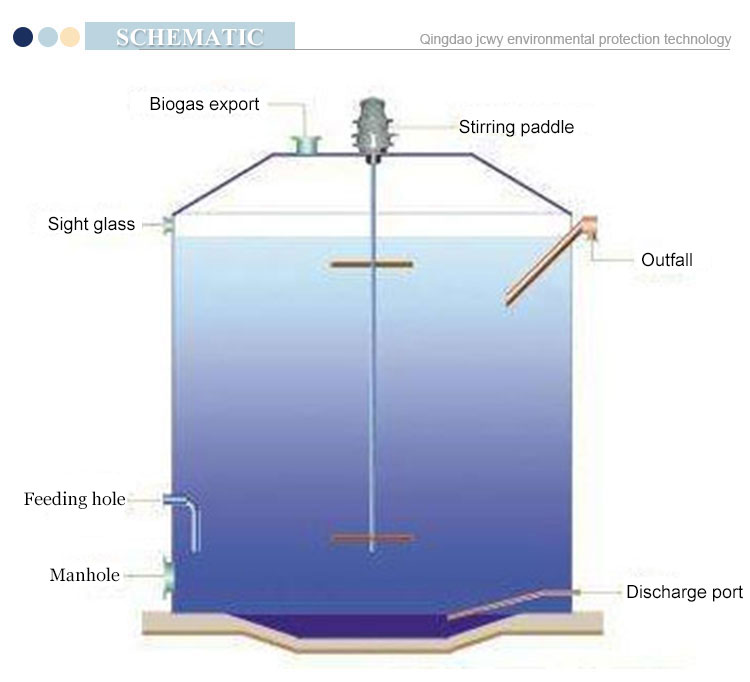

The company formulates reasonable treatment plans for different

pollution sources and adopts the most advanced CSTR, UASB and IC

sewage treatment process enable waste treatment to achieve the

economic and ecological effects of reduction, harmlessness and

recycling. With a professional team, strict management and

excellent equipment, and perfect testing methods, the company

strives to create products that are constantly improving.

The company has passed ISO9001:2008 quality management system

certification and ISO14001:2004 environmental system certification.

And our products are manufactured in strict accordance with

international ISO9001 quality system standards, and our business

spreads all over the world. Our high-standard production technology

and reasonable price have won the praise of a large number of

customers.